Air Recirculation Bio-Reactor ARB

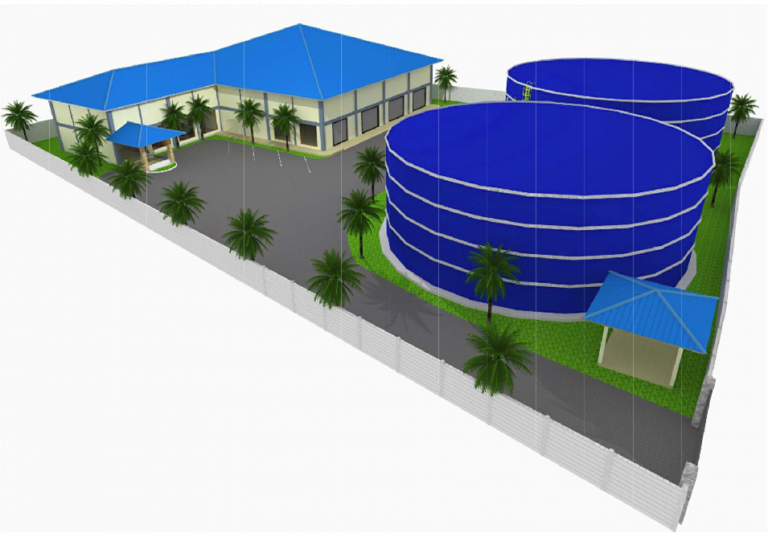

Biosystems are design built modular ARB Sewage Treatment Plants with capacities ranging from 20m3/day to 3000 m3/day. Our static and containerized STP system are engineered and designed using the most cost effective process technology – The Forced Draft High Rate Bioreactor process is known world-wide to be the lowest in running cost to treat domestic sewage. The technology uses only 30% of the power requirement compared to conventional Extended Aeration or Activated Sludge Processes

Biosystems Air Recirculation Bioreactor STP/ wastewater treatment plants are designed to treat domestic strength sewage, to achieve treated effluent, suitable for reuse in industrial applications or for irrigation.

With the addition of Xline Filtration &a sterilization module, Class A treated effluent, suitable for reuse in process water, can be achieved.

Biosystems technology evolved out of two decades of research and development with innovative wastewater treatment including recognition of the latest developments in ARB Cross-Flow Bio Media Air Recirculation Bio Reactor

Result: A Series of new concepts that simplified and enhanced the process performance and reliability.

This technology is the basis of a ARB t Enclosed Air Recirculation Bio Reactor.

It employs the familiar Gross Flow Bio Media, accommodates influent flows continuously and accomplishes nitrification, denitrification and clarification, all in a modular system. The Biosystems ARB Process features allow for design flexibility that contributes to substantial market advantages.